Ever really thought about how print head materials impact receipt printer performance? This consideration is often overlooked, but the material selected influences print quality, speed, and durability.

By using Rohm ceramic print head, our product will be improved by better print quality, and reduced printer maintenance. Selecting the correct material can lead to cost and better performance of the printer.

We’ll be discussing how different print head materials can affect the performance of your printer in this article.

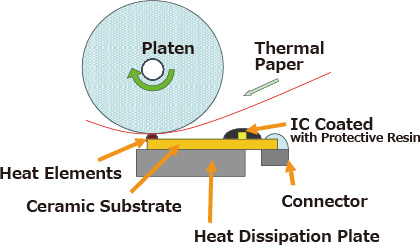

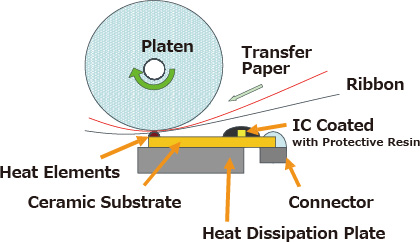

In thermal printers, a thermal printhead is a vital part that produces text and images by applying heat to specific materials(such as thermal paper or thermal transfer ribbons). This process includes a number of heating elements placed on a substrate, and are activated by driver ICs to produce precise prints.

There are two main types of printing methods that utilize thermal printheads and Direct Thermal Printing and Thermal Transfer Printing. Both, however, have unique features and uses.

Direct Thermal Printing

Advantages:

Disadvantages:

Thermal Transfer Printing

Advantages:

Disadvantages:

Thermal printheads are used in both direct thermal and thermal transfer printing; however, the two methods display prints differently by utilizing heat. Direct thermal printing is simple and economical for temporary use, but its output lacks durability. Thermal transfer printing, on the other hand, offers greater durability and is typically used for longer-term applications.

Receipt printers, especially thermal printers, are highly dependent on the materials used in a print head for performance. Here are some key points to keep in mind:

| Aspect | Details |

|---|---|

| Wear and Tear | Material abrasion due to direct contact with thermal paper. Using high-quality, smoother paper reduces wear. |

| Heat Transfer Efficiency | The efficiency of heat transfer depends on material conductivity. Better conductivity improves print quality and speed. |

| Durability and Lifespan | High-quality materials extend lifespan, reduce maintenance costs, and offer corrosion resistance in humid or chemical environments. |

| Print Quality | The precision and consistency of heating elements determine print clarity and quality. High-quality materials ensure uniform heat distribution. |

| Cost and Maintenance | Material costs affect overall printer cost and maintenance. Durable materials may be expensive upfront but save on long-term costs by extending lifespan. |

Here are the key benefits of ROHM printheads used in most of our thermal printers(eg. 80mm Thermal Cloud Receipt POS Printer) in our company.

Power Efficiency and Performance

Compact Design with Enhanced Portability

Cutting-Edge Technology and Personalization

Reliability and Durability

The choice of materials for printheads is critical to achieving an optimal balance of speed, quality, durability, and cost. For businesses seeking to optimize their thermal printers' performance, investing in high-quality printheads ensures better results over time.

If you're looking to find a thermal printer manufacturer that uses high-quality printheads, contact our team today for personalized recommendations!How Do Printhead Affect the Performance of Receipt Printers?